Glynne Bowsher

Glynne earned his BEng in Mechanical Engineering from UWIST Cardiff in 1962. At Girling he designed brakes, friction materials, test equipment and quality control techniques related to the automotive and friction materials industries. As a senior design engineer he worked in projects involving pumps and vehicle power hydraulics. He continued working on brakes with diesel engines and transmission systems for a brake-testing dynamometer and test-heads for railway and fluid-cooled brakes. He also worked on brakes and hydraulic systems for tramcars.

Glynne designed the brakes and power break system for the

Thrust 2 car that set a new land speed record in 1982. After that endeavor

he worked on patented electric breaks. He developed hydraulic breaks for

trains and transmission brakes for the TGV, and hydraulically actuated

brakes for the Docklands Light Railway. In the automotive arena he

designed traction-control systems for use within existing ABS systems. The

challenge of trying to set a new land speed record and to break the sound

barrier called Glynne back into partnership with Richard Noble.

Glynne designed the brakes and power break system for the

Thrust 2 car that set a new land speed record in 1982. After that endeavor

he worked on patented electric breaks. He developed hydraulic breaks for

trains and transmission brakes for the TGV, and hydraulically actuated

brakes for the Docklands Light Railway. In the automotive arena he

designed traction-control systems for use within existing ABS systems. The

challenge of trying to set a new land speed record and to break the sound

barrier called Glynne back into partnership with Richard Noble.

Glynne became the Chief Mechanical Engineer and co-founder of the Thrust SSC (Super Sonic Car) project. He was responsible for the design of the wheels, breaking, steering and suspension systems. Glynne had gained invaluable experience in designing the high-speed breaks and wheels for the earlier Thrust2 project. Glynne chose Helix as his CAD system due to his familiarity with mainframe CADAM® while working at Lucas Automotive, the world's leading brake/chassis manufacture. He was able to use Helix to exchange data with numerous and widely scattered partners, which was essential to meeting the overall project schedule. MICROCADAM Limited was an earlier supporter and official sponsor of this UK based operation.

A major challenge for Mr. Bowsher was how to stop a car traveling at

nearly 800-mph. Since no tire could withstand the abuse at these speeds,

the decision had been made to run the car on its rims. His design

consisted of two systems: a parachute system to slow the car to 200 mph

and a carbon fiber break system to bring the car to a final halt. The team

had analyzed the internal load on the wheels with finite element analysis.

These studies showed that centrifugal forces would tear them apart through

the axle hole. They decided to create external bearing holders that clamp

on both sides of the wheel disc allowing the wheel center to be

solid.

On October 15, 1997 ThrustSSC became the first super sonic car and set a new land speed record of 763.035 mph, Mach 1.02. For his contribution to this effort, Glynne was awarded an honorary Dr of Science degree from Southampton University.

British Steam Car Challenge

This began as a student project within the mechanical engineering department of Southampton University. The project obtained sponsorship from Ecological Engine Company and they have engaged Glynne Bowsher as their designer. The goal, a century after the Stanley Steamer was introduced, is to set a new land speed record for a steam car. They are shooting for 150 mph, although the car will be design to reach 200 mph.

The car will be much lighter than the old conventional steam vehicles and unlike its antiquated ancestors it will not rely on potentially polluting fuels like coal or oil. Instead it will use liquid petroleum gas or liquefied hydrogen and a compact boiler. The materials now available can withstand much greater temperatures and pressure, increasing efficiency tremendously.

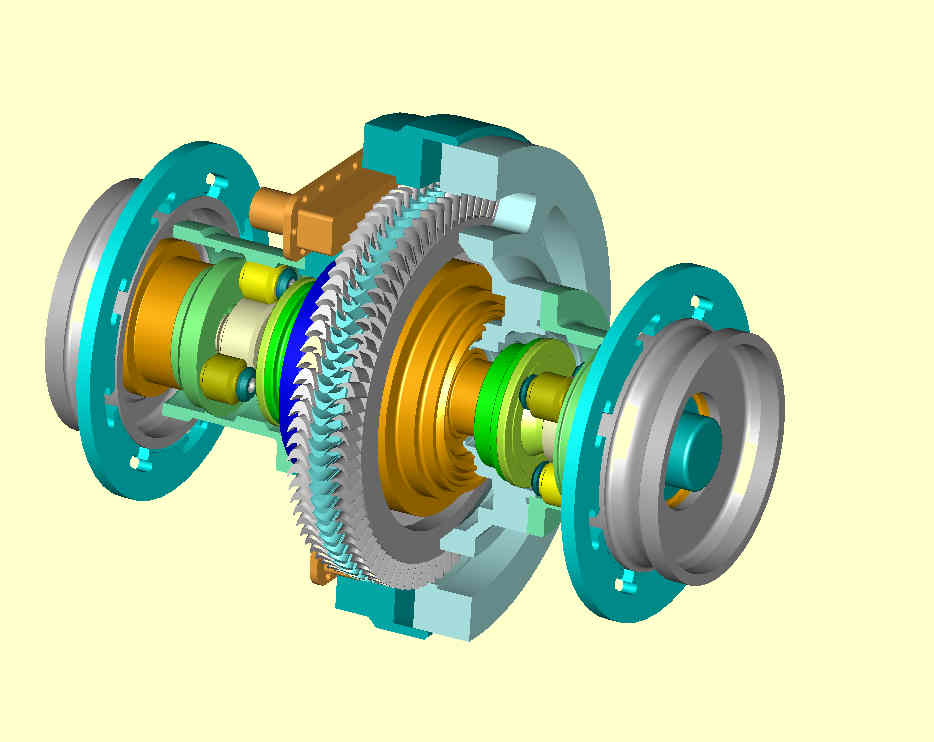

Steam Car Engine

The subcontractor department, on the other hand, uses Helix Drafting to produce cutting programs for the flame cutting machine. The drawings used can be delivered either on ordinary paper, floppy discs, or by e-mail. For this task, DCADAM developed a program that converts Helix drawings into Essi-codes which can be used by the flame cutting machines.

In 1906 a Land Speed Record for steam powered vehicles was set at Ormond (now called Daytona) Beach, Florida, by the Stanley works driver, Fred Marriott, in a modified steam race car. His terminal speed of 127.66 MPH was the fastest that ANY human being had ever achieved in a motor vehicle. In a later attempt the car was wrecked and the driver nearly killed. Before the crash the car was traveling at an estimated 150 mph. The Stanley brothers gave up racing after that near fatality. Marriott's record was beaten by more powerful petrol driven vehicles, but his Steam Land Speed Record lived on for almost 80 years. It was only bettered in when Bob Barber, another American, raised the record to 145.607 MPH in a modern steam turbine car.

Stanley Steamer History

The Stanley twins, Francis Edgar and Freelan

Oscar, were partners in a photographic dry plate business in Newton,

Mass., where they produced their first light steam car in 1897. This

proved to be a great success with over 200 being sold in the first year of

manufacture. The cars were sold under the names Locomobile and Mobile by a

company who had purchased the manufacturing rights. The Stanleys developed

a new design and reentered the business. They sold their photographic

related business to George Eastman (Kodak) in order to concentrate on

their automotive business. In 1898 a Stanley was timed over a mile in

Charles River Park at 27.40 m.p.h. In 1899 Stanley drove the steamer to

the summit of Mount Washington. During the late eighteen hundreds the

steam car outsold the internal combustion cars from the likes of Olds. In

1902 the Stanleys introduced a new design, with a simple non-condensing

engine driving directly on the rear axle. The boiler was mounted at the

front, frames were of wood, and steering was by tiller. By 1908 the cars

were capable of 60 mph and could travel 50 miles before needing a refill.

Although the steam car operated almost silently, had no gears to shift and

ran with practically no vibration, it did have its drawbacks The main

drawback of the steamer was the nearly half-hour it took to heat the water

and build up the pressure. A foot and mouth disease epidemic in the

Stanleys New England home area in 1914 caused the removal of many roadside

horse troughs that owners relied on for refills. In 1915 a new design was

introduced which featured a steel frame and aluminum body. What appeared

to be a V-prow radiator up front was actually the Stanley's first

condenser, allowing exhaust steam to be recycled and vastly extend the

cars range. The advent of Cadillac's self-starter in 1912 really signaled

the end of the steamer. By then internal combustion cars were advancing

quicker technologically and greatly outselling the steam car.

The Stanley twins, Francis Edgar and Freelan

Oscar, were partners in a photographic dry plate business in Newton,

Mass., where they produced their first light steam car in 1897. This

proved to be a great success with over 200 being sold in the first year of

manufacture. The cars were sold under the names Locomobile and Mobile by a

company who had purchased the manufacturing rights. The Stanleys developed

a new design and reentered the business. They sold their photographic

related business to George Eastman (Kodak) in order to concentrate on

their automotive business. In 1898 a Stanley was timed over a mile in

Charles River Park at 27.40 m.p.h. In 1899 Stanley drove the steamer to

the summit of Mount Washington. During the late eighteen hundreds the

steam car outsold the internal combustion cars from the likes of Olds. In

1902 the Stanleys introduced a new design, with a simple non-condensing

engine driving directly on the rear axle. The boiler was mounted at the

front, frames were of wood, and steering was by tiller. By 1908 the cars

were capable of 60 mph and could travel 50 miles before needing a refill.

Although the steam car operated almost silently, had no gears to shift and

ran with practically no vibration, it did have its drawbacks The main

drawback of the steamer was the nearly half-hour it took to heat the water

and build up the pressure. A foot and mouth disease epidemic in the

Stanleys New England home area in 1914 caused the removal of many roadside

horse troughs that owners relied on for refills. In 1915 a new design was

introduced which featured a steel frame and aluminum body. What appeared

to be a V-prow radiator up front was actually the Stanley's first

condenser, allowing exhaust steam to be recycled and vastly extend the

cars range. The advent of Cadillac's self-starter in 1912 really signaled

the end of the steamer. By then internal combustion cars were advancing

quicker technologically and greatly outselling the steam car.

The twins retired from active participation in the car business in 1917, although they continued to tinker. F.E. experimented with spool-shaped piston valves, which would allow higher steam pressures and thus greater horsepower. On July 31, 1918, while driving a car equipped with these valves, F.E. flipped his car trying to avoid pedestrians and was killed. F.O. was grief-stricken and soon devoted all his time to his tourist resort in Estes Park, Colorado. He died in Newton, Massachusetts, in 1940.